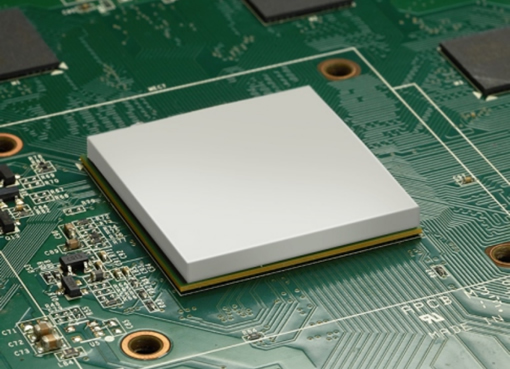

Dachuang Kehua thermal conductive silicone sheet is a thermal conductive medium material synthesized through a special process using silicone as the substrate and various auxiliary materials such as metal oxides. It is used to reduce the contact thermal resistance between the heat source surface and the contact surface of the radiator component. It is specially designed and produced for using gaps to transfer heat. It can fill gaps, complete heat transfer between the heating and cooling parts, and also serve as insulation, shock absorption and sealing. It can meet the design requirements of equipment miniaturization and ultra-thinness, and is highly processable and practical, with a wide range of thickness applications. It is an excellent thermal conductive filling material. It is used for control main boards, new energy vehicles, LED lighting, communication equipment, computers, PC servers, machine room stations, switching power supplies, backlight modules and any materials that need to be filled and Heat spreader of electronic and electrical products. Material selection content: Thermal conductive silicone sheet, with fiberglass silicone film, with silicone tape silicone film Thermal conductivity range: 1-8W/m · k Thickness range: 0.3-20mm Hardness range: 15-75 degrees (Shore C) Colors: black, light blue, blue, pink, green, purple, yellow

| Item | Standard | Unit | DC1010 | DC1015 | DC1020 | DC1030 |

1 | Thickness | ASTM D374 | mm | 0.3-20 | 0.3-20 | 0.3-20 | 0.3-20 |

2 | ASTM D792 | g/cc | 1.8±0.1 | 1.9 ±0.1 | 2.4±0.1 | 2.9±0.1 | |

3 | Hardness | ASTM D2240 | Shore 00 | 15-50 | 20-50 | 30-50 | 30-60 |

4 | Temperature | EN344 | °C | -40-200 | -40-200 | -40-200 | -40-200 |

5 | Dielectric constant | ASTM D150 | / | 4.8 | 4.8 | 5.3 | 5.4 |

6 | Volumetric resistivity | ASTM D257 | Q-cm | 1.0*10^12 | 1.0*10^12 | 1.0*10^12 | 1.0*10^12 |

7 | Voltage resistance | ASTM D149 | kV/mm | 4 | 4 | 4 | 4 |

8 | Flame retardancy | UL-94 | / | V-0 | V-0 | V-0 | V-0 |

9 | Thermal conductivity | ASTM D5470 | W/m K | 1 | 1.5 | 2 | 3 |

10 | Environmental Testing | RoHS REACH | / | Qualified | |||

11 | Remarks | Cutting and processing of rolls, sheets and backings are available. Special thermal conductivity, performance parameters, width, thickness and color can be customized and adjusted upon request. | |||||

Item | Standard | Unit | DC1040 | DC1050 | DC1060 | DC1080 | |

1 | Thickness | ASTM D374 | mm | 0.3-20 | 0.3-20 | 0.3-20 | 0.3-20 |

2 | ASTM D792 | g/cc | 3.2±0.1 | 3.3 ±0.1 | 3.5±0.1 | 3.5±0.1 | |

3 | Hardness | ASTM D2240 | Shore 00 | 40-60 | 40-60 | 40-60 | 50-75 |

4 | Temperature | EN344 | °C | -40-200 | -40-200 | -40-200 | -40-200 |

5 | Dielectric constant | ASTM D150 | / | 6 | 6.2 | 6.2 | 6.2 |

6 | Volumetric resistivity | ASTM D257 | Q-cm | 1.0*10^12 | 1.0*10^12 | 1.0*10^12 | 1.0*10^12 |

7 | Voltage resistance | ASTM D149 | kV/mm | 4 | 6 | 6.1 | 6.1 |

8 | Flame retardancy | UL-94 | / | V-0 | V-0 | V-0 | V-0 |

9 | Thermal conductivity | ASTM D5470 | W/m K | 4 | 5 | 6 | 8 |

10 | Environmental Testing | RoHS REACH | / | Qualified | |||

11 | Remarks | Cutting and processing of rolls, sheets and backings are available. Special thermal conductivity, performance parameters, width, thickness and color can be customized and adjusted upon request. | |||||