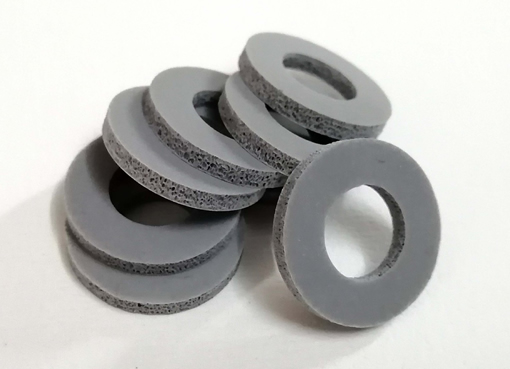

Silicone rubber foaming material (also called silica gel foam/foaming silica gel) is a kind of foam material formed by polysiloxane foaming. Based on the liquid silicone rubber formula, it is porous, low-density and compressible after foaming and curing by adding foaming components High polymer elastomer materials. Silicone rubber foam is increasingly widely used, because it has the excellent performance of both silicone rubber and foam materials, such as high and low temperature ultraviolet and ozone resistance, weather resistance, insulation, environmental protection, as well as the low density, excellent sound absorption, seismic resistance and other characteristics of foam materials. Its excellent compressive deformation and creep resistance, aging resistance, chemical medium resistance, excellent electrical properties, excellent flame retardancy, and mechanical fatigue resistance make it the best material for various high-performance sealing, shock absorption, buffering, sound insulation, protection, insulation, fire prevention, sound absorption and noise reduction. Satisfied with new energy vehicles, rail transit, aerospace, 5G communications, consumer electronics and other industries.

Performance(Unit) | Testing Standard | Data |

| Density(g/cm) | ASTM D 1056 | 0.55 |

| 25% compressive stress(Kpa) | ASTM D 1056 | 150 |

Compression permanent deformation(%) | ASTM D 1056 | <5 |

Tensile strength(Kpa) | GB/T 538-2009 | 700 |

Elongation at break(%) | GB/T 538-2009 | 160 |

| Water absorption rate(%) | ASTM D570 | <2 |

Low temperature embrittlement(°C) | ASTMD 746 | -55°C Qualified |

Flame retardancy | UL 94 | V-0 |

Toxic gas emission level | SMP-800C | Qualified |

Volumetric resistivity(Ω-cm) | ASTM D 257 |  |

Dielectric Strengths(kV/mm) | ASTM D 495 | >3 |

Thermal conductivity(W/(m·K)) | ASTM C 518 | 0.11 |

Maximum smoke density | ASTM E 662 | <150 |

Burning flame spread index | ASTM E 162 | <35 |

Environmental Testing | RoHS REACH Qualified | RoHS REACH Qualified |

Performance(Unit) | Testing Standard | Data |

Density(g/cm) | ASTM D 1056 | 0.5 |

25% compressive stress(Kpa) | ASTM D 1056 | 140 |

Compression permanent deformation(%) | ASTM D 1056 | <5 |

Tensile strength(Kpa) | GB/T 538-2009 | 600 |

Elongation at break(%) | GB/T 538-2009 | 135 |

Water absorption rate(%) | ASTM D570 | <2 |

Low temperature embrittlement(°C) | ASTMD 746 | -55°C Qualified |

Flame retardancy | UL 94 | V-0 |

Toxic gas emission level | SMP-800C | Qualified |

Volumetric resistivity(Ω-cm) | ASTM D 257 |  |

| Dielectric Strengths(kV/mm) | ASTM D 495 | >3 |

Thermal conductivity(W/(m·K)) | ASTM C 518 | 0.11 |

Maximum smoke density | ASTM E 662 | <150 |

Burning flame spread index | ASTM E 162 | <35 |

Environmental Testing | RoHS REACH Qualified | RoHS REACH Qualified |

Performance(Unit) | Testing Standard | Data |

Density(g/cm) | ASTM D 1056 | 0.45 |

25% compressive stress(Kpa) | ASTM D 1056 | 110 |

Compression permanent deformation(%) | ASTM D 1056 | <3 |

Tensile strength(Kpa) | GB/T 538-2009 | 500 |

Elongation at break(%) | GB/T 538-2009 | 130 |

Water absorption rate(%) | ASTM D570 | <3 |

Low temperature embrittlement(°C) | ASTMD 746 | -55°C Qualified |

Flame retardancy | UL 94 | V-0 |

Toxic gas emission level | SMP-800C | Qualified |

Volumetric resistivity(Ω-cm) | ASTM D 257 |  |

Dielectric Strengths(kV/mm) | ASTM D 495 | >3 |

Thermal conductivity(W/(m·K)) | ASTM C 518 | 0.1 |

Maximum smoke density | ASTM E 662 | <150 |

Burning flame spread index | ASTM E 162 | <35 |

Environmental Testing | RoHS REACH Qualified | RoHS REACH Qualified |

Performance(Unit) | Testing standard | Data |

Density(g/cm) | ASTM D 1056 | 0.42 |

25% compressive stress(Kpa) | ASTM D 1056 | 95 |

Compression permanent deformation(%) | ASTM D 1056 | <3 |

Tensile strength(Kpa) | GB/T 538-2009 | 450 |

Elongation at break(%) | GB/T 538-2009 | 120 |

| Water absorption rate(%) | ASTM D570 | <3 |

Low temperature embrittlement(°C) | ASTMD 746 | -55°C Qualified |

Flame retardancy | UL 94 | V-0 |

Toxic gas emission level | SMP-800C | Qualified |

Volumetric resistivity(Ω-cm) | ASTM D 257 |  |

Dielectric Strengths(kV/mm) | ASTM D 495 | >3 |

Thermal conductivity(W/(m·K)) | ASTM C 518 | 0.09 |

Maximum smoke density | ASTM E 662 | <150 |

Burning flame spread index | ASTM E 162 | <35 |

Environmental Testing | RoHS REACH Qualified | RoHS REACH Qualified |

Performance(Unit) | Testing standard | Data |

Density(g/cm) | ASTM D 1056 | 0.35 |

25% compressive stress(Kpa) | ASTM D 1056 | 62 |

| Compression permanent deformation(%) | ASTM D 1056 | <3 |

Tensile strength(Kpa) | GB/T 538-2009 | 350 |

Elongation at break(%) | GB/T 538-2009 | 110 |

Water absorption rate(%) | ASTM D570 | <3 |

Low temperature embrittlement(°C) | ASTMD 746 | -55°C Qualified |

Flame retardancy | UL 94 | V-0 |

Toxic gas emission level | SMP-800C | Qualified |

| Volumetric resistivity(Ω-cm) | ASTM D 257 |  |

Dielectric Strengths(kV/mm) | ASTM D 495 | >3 |

Thermal conductivity(W/(m·K)) | ASTM C 518 | 0.09 |

Maximum smoke density | ASTM E 662 | <150 |

Burning flame spread index | ASTM E 162 | <35 |

Environmental Testing | RoHS REACH Qualified | RoHS REACH Qualified |

Performance(Unit) | Testing stadard | Data |

Density(g/cm) | ASTM D 1056 | 0.30 |

25% compressive stress(Kpa) | ASTM D 1056 | 40 |

Compression permanent deformation(%) | ASTM D 1056 | <3 |

Tensile strength(Kpa) | GB/T 538-2009 | 300 |

Elongation at break(%) | GB/T 538-2009 | 110 |

Water absorption rate(%) | ASTM D570 | <3 |

Low temperature embrittlement(°C) | ASTMD 746 | -55°C Qualified |

Flame retardancy | UL 94 | V-0 |

Toxic gas emission level | SMP-800C | Qualified |

Volumetric resistivity(Ω-cm) | ASTM D 257 |  |

Dielectric Strengths(kV/mm) | ASTM D 495 | >3 |

Thermal conductivity(W/(m·K)) | ASTM C 518 | 0.08 |

Maximum smoke density | ASTM E 662 | <150 |

Burning flame spread index | ASTM E 162 | <35 |

Environmental Testing | RoHS REACH Qualified | RoHS REACH Qualified |

Performance(Unit) | Testing stadard | data |

Density(g/cm) | ASTM D 1056 | 0.25 |

25% compressive stress(Kpa) | ASTM D 1056 | 60 |

Compression permanent deformation(%) | ASTM D 1056 | <3 |

Tensile strength(Kpa) | GB/T 538-2009 | 300 |

Elongation at break(%) | GB/T 538-2009 | 90 |

Water absorption rate(%) | ASTM D570 | <5 |

Low temperature embrittlement(°C) | ASTMD 746 | -55°C qualified |

Flame retardancy | UL 94 | V-0 |

Toxic gas emission level | SMP-800C | qualified |

Volumetric resistivity(Ω-cm) | ASTM D 257 |  |

Dielectric Strengths(kV/mm) | ASTM D 495 | >3 |

Thermal conductivity(W/(m·K)) | ASTM C 518 | 0.08 |

Maximum smoke density | ASTM E 662 | <150 |

Burning flame spread index | ASTM E 162 | <35 |

Environmental Testing | RoHS REACH qualified | RoHS REACH qualified |

Performance(Unit) | Testing Standard | Data |

Density(g/cm) | ASTM D 1056 | 0.15 |

25% compressive stress(Kpa) | ASTM D 1056 | 8 |

Compression permanent deformation(%) | ASTM D 1056 | <3 |

Tensile strength(Kpa) | GB/T 538-2009 | 200 |

Elongation at break(%) | GB/T 538-2009 | 90 |

Water absorption rate(%) | ASTM D570 | <5 |

Low temperature embrittlement(°C) | ASTMD 746 | -55°C Qualified |

Flame retardancy | UL 94 | V-0 |

Toxic gas emission level | SMP-800C | Qualified |

Volumetric resistivity(Ω-cm) | ASTM D 257 |  |

| Dielectric Strengths(kV/mm) | ASTM D 495 | >3 |

Thermal conductivity(W/(m·K)) | ASTM C 518 | 0.05 |

Maximum smoke density | ASTM E 662 | <150 |

Burning flame spread index | ASTM E 162 | <35 |

Environmental Testing | RoHS REACH Qualified | RoHS REACH Qualified |

Performance(Unit) | Testing Standard | Data |

Density(g/cm) | ASTM D 1056 | 0.2 |

25% compressive stress(Kpa) | ASTM D 1056 | 15 |

Compression permanent deformation(%) | ASTM D 1056 | <3 |

Tensile strength(Kpa) | GB/T 538-2009 | 300 |

Elongation at break(%) | GB/T 538-2009 | 90 |

Water absorption rate(%) | ASTM D570 | <5 |

Low temperature embrittlement(°C) | ASTMD 746 | -55°C Qualified |

Flame retardancy | UL 94 | V-0 |

Toxic gas emission level | SMP-800C | Qualified |

Volumetric resistivity(Ω-cm) | ASTM D 257 |  |

Dielectric Strengths(kV/mm) | ASTM D 495 | >3 |

Thermal conductivity(W/(m·K)) | ASTM C 518 | 0.07 |

Maximum smoke density | ASTM E 662 | <150 |

Burning flame spread index | ASTM E 162 | <35 |

Environmental Testing | RoHS REACH Qualified | RoHS REACH Qualified |

Performance(Unit) | Testing Standard | Data |

Density(g/cm) | ASTM D 1056 | 0.25 |

25% compressive stress(Kpa) | ASTM D 1056 | 25 |

Compression permanent deformation(%) | ASTM D 1056 | <3 |

Tensile strength(Kpa) | GB/T 538-2009 | 300 |

Elongation at break(%) | GB/T 538-2009 | 110 |

Water absorption rate(%) | ASTM D570 | <5 |

Low temperature embrittlement(°C) | ASTMD 746 | -55°C Qualified |

Flame retardancy | UL 94 | V-0 |

Toxic gas emission level | SMP-800C | Qualified |

Volumetric resistivity(Ω-cm) | ASTM D 257 |  |

Dielectric Strengths(kV/mm) | ASTM D 495 | >3 |

Thermal conductivity(W/(m·K)) | ASTM C 518 | 0.08 |

Maximum smoke density | ASTM E 662 | <150 |

Burning flame spread index | ASTM E 162 | <35 |

Environmental Testing | RoHS REACH Qualified | RoHS REACH Qualified |